Characteristics of heat-resistant wire PRKA

Labeling Explanation

The wire of the PRKA brand belongs to the heat-resistant mounting and is decrypted as follows:

- P - wire made with a copper core;

- RK - a shell made of organosilicon (silicone) rubber, it does not contain halogens, while it is impregnated in the form of an antiseptic composition;

- A - has increased hardness (here the letter "A" means far from aluminum, as most might have thought, because the core is made of copper in this conductor).

Design Features

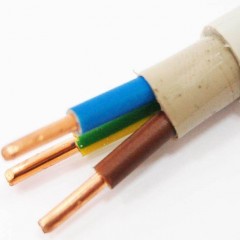

The PRKA design is a conductive core that is twisted from a number of copper wires (this can be seen in the photo below).

The insulation (sheath or braid) is made of silicone rubber, it can be green, white, red, yellow, blue, black, brown.

There is a kind of wire PRKA-T. The letter "T" means tropical performance; it is used for fixed installation in electric stoves, ovens, as well as other electric heaters used in everyday life. The characteristics of the RCA will be considered in more detail below.

main parameters

Here are the main technical characteristics of the PRKA wire:

- TU 16-505.317-76 (the manufacture of the conductor is regulated by standard 26445 - 85).

- Number of cores: one (when marking is not indicated, since one core is used in all RCAs by default).

- Minimum wire cross section - 0.5 mm2maximum 2.5 mm2. Further, a more detailed table of cross sections will be presented, including weight and possible sizes (all parameters are nominal).

| Core section, mm2 | Insulation thickness (radial), mm | Outer diameter mm | The mass of one kilometer, kg |

| 0,5 | 0,6 | 2,1 | 8,7 |

| 0,75 | 0,6 | 2,3 | 11,6 |

| 1,0 | 0,6 | 2,5 | 14,0 |

| 1,5 | 0,6 | 2,8 | 19,5 |

| 2,5 | 0,8 | 3,7 | 30,3 |

It's important to know! The lower limit deviation from the shell thickness is ten percent. The value of the upper deviation is a non-normalizable value, however, it is not recommended that the value of the outer diameter exceed the maximum deviation. In turn, the value of the upper limit deviation from the outer diameter is twenty percent. Rationing of the lower limit deviation is absent.

In addition to the above, it is important to note the following specifications:

- the ambient temperature in which this wire can be used is in the range from + 180 ° C to -60 ° C;

- maximum working temperature: + 180 ° C;

- PRKA can be operated at 98% humidity level at a temperature of 35 ° C;

- alternating current, frequency 50 Hz, operating voltage 660 V;

- test alternating voltage with a frequency of 50 Hertz (within five minutes) - 2500 Volts;

- pulse voltage - from 4 to 5.6 thousand volts;

- insulation resistance is not less than 100 MOM * km;

- construction wire length from 200 m;

- possesses the following important properties: retains its shape, is elastic, elastic, very durable, while the bending radius is 2 outer diameters;

- isolation of PRKA is resistant to bursting, and it is not afraid of mold exposure;

- the wire does not spread combustion, has a small smoke and gas emission, therefore it is resistant to ozone, as well as solar radiation;

- service life - more than 10 years.

- installation can be carried out at an air temperature of at least -15 ° C.

This wire is made by no manufacturer, if desired, you can find many such manufacturers. Meanwhile, almost every plant is ready to provide a guarantee for the use of the conductor for a year and a half, which is important. ABOUT top cable manufacturers We talked in a separate article.

Application area

Consider where the PRKA wire is used. Its main purpose is the use for connecting in “extreme” places where there is an increased air temperature and humidity, for example, in a bath, sauna, drying chamber, as well as for connecting electric heating household devices (as mentioned above in the description of PRKA-T) , electric motors, electric fireplaces, lighting and heating appliances with high power. It is precisely the technical specifications that make it possible to operate the PRKA under such rather severe conditions.

Finally, we recommend watching a useful video in which heat-resistant wires (including the PRKA brand) are considered, as well as the scope of each embodiment:

So we examined the main technical characteristics of the PRKA wire, the decoding of the marking and possible conductor cross-sections. We hope the information provided was useful and understandable for you!

It will be interesting to read: