Characteristics of the control cable KVVG

Explanation of the designation

The abbreviation KVVG is deciphered as follows:

- K - control cable;

- In - internal isolation from polyvinylchloride plasticizer;

- B - means that the external insulation is also made of PVC;

- G - flexible, core class I, the smaller the number (closer to I) in the flexibility class, the more flexible the conductor we get.

The control cable is usually multi-core. KVVG is produced with a different number of cores from 4 to 61. If the letter “E” is added to the marking, then a shielding layer is added. It is needed to protect the line from crosstalk other lines located nearby.

Varieties with NG and NG-ls in the marking indicate a non-combustible cable and a variant with minimal distribution of combustion products. This must be taken into account when working in elevated temperatures.

Another important point: KVVG - copper cable, and AKVVG - aluminum. Thus, the description and composition is contained in the title.

Design Features

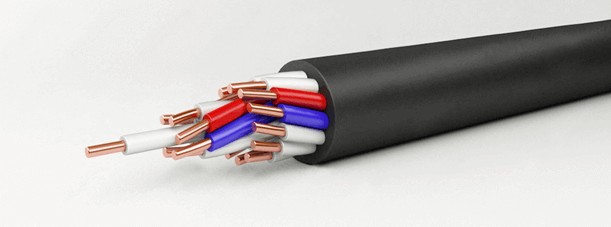

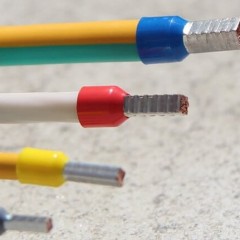

Since the cable KVVG is multi-core for the convenience of working with it, the conductors may have color marking (if the letter “C” is added to the name), in the form of a strip, solid color or digital.

Depending on the cross-sectional area, the cable can contain from 4 cores up to 61. They can be additionally wrapped with tape from polyethylene or polyamide film, or cable or telephone paper. It is needed to separate the core from the external insulation and ensure their mobility. Perhaps its absence, if these conditions are met.

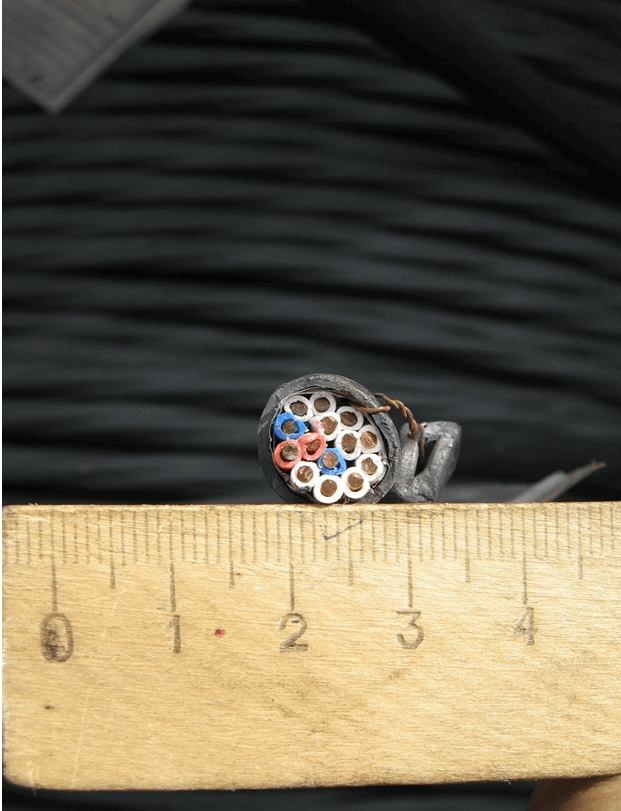

The design of the wires was as follows: the central vein, around it the first row, the second row and so on. Cores are twisted along a cable like a spiral. At the same time, a counting pair is present in each row; in any version of the HVAC, it has red and blue insulation.

A counting pair is needed for the correct determination of the ends, a report from it in one direction or another. This is very convenient when installing electrical equipment, when the cable is already laid, and its ends are so far apart that it is not possible to ring the match without the use of additional technical means.

In the video below, the design of the KVVG cable is visually examined:

Specifications

The KVVG cable can be used in installations of 660 Volts and 100 Hz with an alternating voltage frequency. The maximum voltage of direct current installations is 1000 V. The test of the conductor is carried out at 2500 V. KVVG can be put into operation at ambient temperatures from -50 to +50 degrees Celsius. The maximum allowable temperature is –70 degrees Celsius.

Important! The considered brand of cable can not be subjected to mechanical stress and loads, when laying it is necessary to take into account in advance all factors that can lead to sagging, vibrations, longitudinal tension and others. Subject to these conditions, the service life of KVVG laid in the tunnel, in the corrugation or channel is 25 years, and in the open air and in rooms with high humidity and other harmful factors - 15 years.

Characteristics of the KVVG cable that you should be aware of:

- Normal cable insulation resistance if it is polyethylene - 300 MΩ, PVC - 6 MΩ.

- The insulation thickness is from 0.6 to 0.8 mm, depending on the cross-sectional area of the cores (the larger the thicker).

- The construction length of KVVG is 150 meters, but it is also found in bays with a different amount of cable.

- Size range from 0.75 mm2 each core up to 10 mm2, from 4 to 61 veins.

Cables with conductors up to 1.5 mm2 may contain a maximum number of cores - 61. Well, in the case of sections of 4-6 mm2 - from 4 to 10. Some manufacturers can produce KVVG and with two conductors of 0.5 mm each2 other.

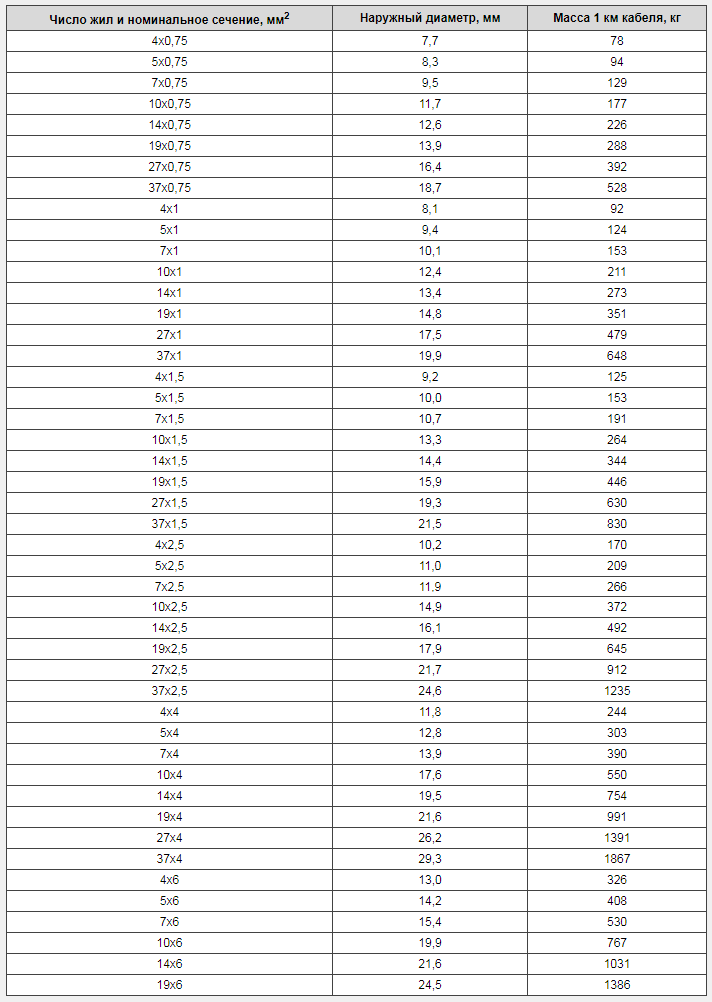

The weight of the line depends on both the diameter of the conductors and their quantity. Below is a table where in the first column the number of cores and their cross-section, in the second, the dimensions of the outer diameter of the HVAC, in the third - weight (kg per km).

Application area

KVVG refers to control cables, their scope is control circuits and control circuits. At the same time, a wide size range indicates that it is not low-current. Its main purpose is to manage any, even powerful contactors and receive information from sensors and limit switches.

Technical characteristics make it possible to withstand the operation of actuators, such as heat guns and electric motors, but power cables are better for connecting them.

Manufacturers

Among domestic manufacturers there are enough representatives of these products:

- LLC "RT RT-Cable"

- LLC "Rybinskkabel"

- LLC "Plant Agrocable"

- JSC Belaruskabel

- LLC "TD" VOKZ "

- LLC "TD Voronezhtelekabel"

- JSC Cable Factory Kavkazkabel

- OJSC NP Podolskkabel

- Pskovkabel OJSC

- LLC "Rybinskkabel"

- Sibcable JSC, KhKA LLC

- LLC GC Sevcable

- LLC Tomskkabel

The conductor is produced in accordance with GOST 1508-78 and has the corresponding characteristics. Analogs:

- NYY

- (N) YM (St);

- NYM-J;

- NYM-O;

The technical characteristics of the KVVG cable and the assortment of cross-sections allow it to be used in a wide range of electrical installations. Stranded versions will save space in the cable tray and improve the final appearance and durability of the installation with automated control, as well as the installation of operator switchboards with a large number of adjustments and sensors. We hope that the information provided was understandable and useful for you!

We also recommend reading: