Types and sizes of corrugations for cable

Corrugation purpose

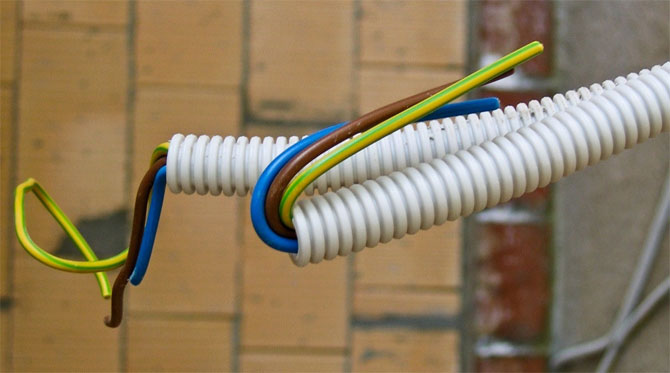

Corrugation for wiring in the General case is a pipe with fins. It is needed to protect the cable or wire from mechanical influences, environmental factors such as elevated temperature and humidity. Corrugation also acts as an additional insulating layer, although weak, but this is not its main function. It also protects the wiring from fire. This property is ensured through the use of appropriate materials, which, when the temperature rises or the cable ignites, begin to melt and release substances that impede combustion.

To connect several segments of the corrugated pipe, lay the cable in it at right angles and divert from the line, appropriate couplings, turns and tees are used. If the installation is carried out correctly, and at the ends the plugs with a slot are put on, then the line is additional protected from moisture.

Types and types of corrugated pipes

Corrugation for the cable is distinguished by the following parameters:

- Diameter.

- The thickness of the walls.

- The materials used.

- Color.

- Resistance to stress.

The flexibility of the corrugation and its stability depends on the thickness of the walls and the material from which it is made. From the materials used depends on the conditions in which it can be used.

Classification by material and its main characteristics:

- PVC is the most common option. Non-combustible and relatively cheap corrugation for wiring. When exposed to UV radiation, it collapses, which imposes restrictions on street use.

- Polyethylene and polypropylene (PPR). Distinguish corrugated pipe made of low polyethylene (HDPE) and high (LDPE) pressure. Operated in the temperature range from -40 to +45 degrees Celsius. Resistant to UV rays, acids, oils and solvents. They are distinguished by colors: black and two-layer red - polyethylene, and blue - polypropylene.

- Metal corrugation. She is also called a metal hose. They provide good cable protection against mechanical damage. Resistant to active substances and oils.

Interesting!The marking of metal hoses is deciphered as follows: RZ-Ts, RZ-TsH, RZ-TSA - made of galvanized steel; RZ-SL and RZ-SL-X - from tinned steel tape; РЗ-ЦП - with PVC insulation, for sealing.

By the number of layers are distinguished:

- Single layer. PVC sleeves most often consist of just one layer, while its thickness can be different.

- Two-layer. An example is a double-walled HDPE pipe.

Resistance to loads:

- Light (up to 320 N / 5 cm2) - the walls are thin and flexible.They are placed on suspended ceilings and in drywall constructions.

- Medium (up to 750 N / 5 cm2) - fit into the shtroba.

- Heavy (withstand up to 1250 N / 5 cm2) - the most rigid, laid in concrete screeds.

- Extra heavy reinforced (up to 4000 N / 5 cm2 and higher). They are laid underground or suspended on supports during outdoor installation.

Another factor is the variety of corrugations in color. Normally, this is not fixed, but usually gray and white PVC corrugations, red, black and blue polyethylene. There are also color models, it depends on which dye is added to the mass at the factory. You can use specific colors for each type of line:

- White - lighting and the Internet.

- Gray or black - sockets, general purpose chains.

- Green - data cables and telephony.

- Red - for external use.

In practice, this separation is not common.

The corrugation wall thickness lies in the range of 5-15 mm. The outer diameter for PVC corrugation is in the range of 16-50 mm. Below is a detailed table that shows the size range of the corrugations for the cable.

| Outside diameter | Inner diameter |

| 16 | 10.7 |

| 20 | 14.1 |

| 25 | 18.3 |

| 32 | 24.5 |

| 40 | 31.5 |

| 50 | 39.6 |

Size range of metal hoses:

| Outside diameter | Inner diameter |

| 9.8 | 5.1 |

| 11.0 | 7.7 |

| 13.5 | 9.7 |

| 15.6 | 11.7 |

| 19.0 | 14.7 |

| 22.0 | 18.0 |

| 38.0 | 31.5 |

| 45.0 | 37.5 |

| 58.0 | 49.5 |

| 71.5 | 62.5 |

| 87.5 | 78.0 |

Versions with and without a probe are also distinguished. The probe is often called a wire pull. This is a thin steel wire to which the wires are tied and with its help the wiring is pulled into the sleeve. This is especially convenient when using conductors with flexible multi-wire cores.

How to choose a corrugation

To figure out which corrugated pipe to buy: HDPE or PVC, we will consider typical applications for different types of corrugations.

PVC is suitable for:

- Outdoor wiring strips in a wooden house.

- To connect the electrical wiring of the fixtures in the suspended ceiling and behind the panels of plastic and GKL.

- Wiring in the bathhouse, in the bathroom and other places with high humidity.

- It is the most common and most often used during installation in an apartment or in a house.

- For outdoor use, but under the condition that direct sunlight is minimized.

HDPE or LDPE, including two-layer ones, are suitable for laying cables in the ground (in the trench) and on the street.

A metal hose is used for laying wires and cables in places with an increased likelihood of mechanical damage. It can be used in explosive rooms. There are options with flanges at the ends and a sealing layer - for use in damp places. Therefore, you can not clearly say which is better, each corrugation has its own application.

An important point is the correct choice of the diameter of the corrugation for the cable. To lay the cable in this way, it must fit into the corrugated pipe, in addition, sometimes it is necessary to lay several wires in one pipe. For one wire you need:

- Determine the inner diameter of the corrugation.

- Determine the outer diameter of the cable.

The table below shows the outer diameters of popular cable products.

| A type | Outer diameter mm |

| VVG 3x1.5 | 8 |

| VVG 3x2.5 | 9.4 |

| VVG 3x4 | 10.8 |

| VVG 3x6 | 11.9 |

| PVA 3x1.5 | 8.2 |

| PVS3x2.5 | 9.8 |

| PVA 2x2.5 | 9.1 |

| VBBSHV 3x4 | 15.5 |

| VBBSHV 3x6 | 16.5 |

For example, to lay electrical wiring from one VVG 3x4, you need a corrugation with an outer diameter of 20 or 25 mm, and for VBbShv 3x4 - 25-32 mm.

Whereas for laying several wires you need to use the following algorithm:

- According to the outer diameter, we calculate the total cross-sectional area of the cable and the cross-sectional area of the corrugation hole.

- The wiring should not fill the corrugated pipe by more than 35%, more details in PUE 2.1.61.

For example, we solve the problem:

It is necessary to lay electrical wiring to connect several powerful spotlights, is there a 2x2.5 PVA wire, how many will fit in a PVC corrugation with a diameter of 50 mm?

Based on the tables above, we determine the outer diameter of the wire and the inner corrugation:

PVC 2x2.5 - 9.1

Corrugations - 39.6

Wire = (n * d ^ 2) / 4 = (3.14 * 9.1 ^ 2) / 4 = 65 sq. mm

Sgofra = (3.14 * 39.6 ^ 2) / 4 = 1231 sq. mm

At the same time, only 35% of the area can be filled:

1231 * 0.35 = 430 sq. Mm

Then the number of wires in one corrugation is equal to:

430/65=6.61

It follows that up to 6 PVA 2x2.5 wires can be inserted into a corrugation of 50 mm.

Now you know how to choose a corrugation for a cable, as well as what sizes and types of products exist today. Finally, we recommend watching useful videos on the topic:

Related materials:

Hello! I need to lay a cable in the garden from the pillar to the plot. Between the site and the pillar is a garden road. Tell me which corrugation to choose. Regards, Yuri.