Types and features of the use of metal hose for cable

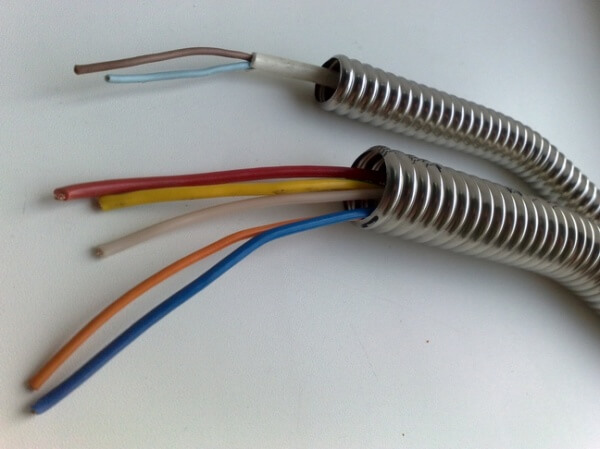

A kind of metal sleeves

Depending on the conditions in which the cable will work, the following types of metal hoses are offered for its protection:

- Made of galvanized steel strip.

- For the manufacture of which stainless steel tape is used.

- In PVC insulation.

Practice shows that at home and on a production scale, sleeves made of galvanized steel are the most popular. Stainless steel is an expensive thing, its scope is distributed in exceptional places of cable laying, where it can be exposed to aggressive chemical environment.

Specifications

First, consider the basic parameters of a galvanized steel hose. The starting material for the manufacture of this type of hose is a metal galvanized plate with a thickness of three microns. The gap between the turns of twisted plates is sealed:

- cotton fabric for products of the brand RZ-TsH;

- polypropylene film for products brand RZ-SL.

The features of this design provide the flexibility of mounted cable lines, reliable protection against damage and exposure to dust and dirt, and the option with a polypropylene sealant can withstand intense humidity loads. These characteristics make it possible to successfully use these hoses when mounting both open and hidden wiring. The use of this type of cable protection is recommended in electrical circuits serving ventilation, heating and air conditioning systems. Due to the metal shell providing a high degree of protection against fires, the sleeve can be used for mounting open wiring on wood. The metal plate from which the electrical product is twisted serves as a screen and protects the wiring from exposure electrical interference. Based on the above material, the main advantages of the metal hose can be distinguished:

- Strength and ability to withstand mechanical damage.

- The ability to provide protection against exposure to dust, dirt and moisture.

- High degree of fire safety.

- The ability to withstand electrical noise.

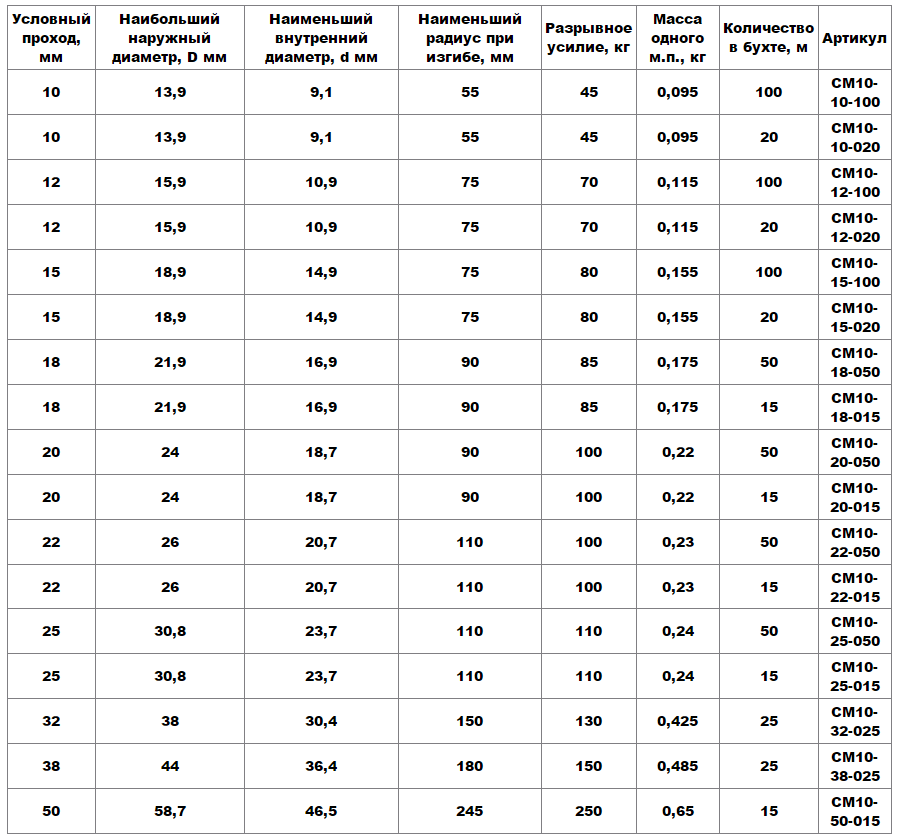

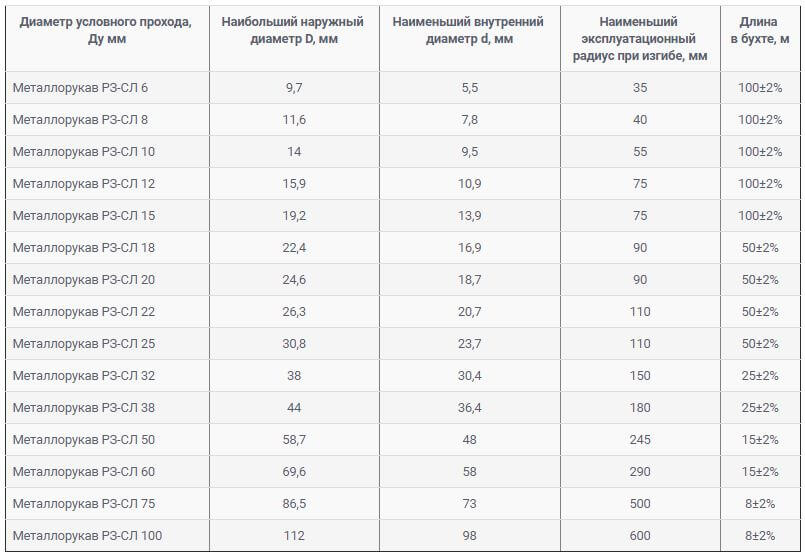

Given the needs of electrical installation, manufacturers mastered the production of a very wide range of internal diameters of metal hoses, from 10 to 100 mm.

Technical characteristics of metal sleeves of the RZ-TsH and RZ-SL brand:

Now consider a metal hose in isolation from polyvinyl chloride (PVC). Popular brands: РЗ-ЦП and МРПИ. The manufacturing technology of this type of hose and a set of positive qualities remain the same as for previous products. The difference is that they are made with an insulating PVC coating, providing a higher degree of protection. The presence of an insulating layer classifies this type of metal hoses as a sealed structure, with high resistance to corrosion, which makes it suitable for use in underground utilities, tunnels and in explosive rooms.

It is especially important to know that this type of hose is by no means suitable for working under water, as well as for laying outdoors, in regions with low temperatures. The fact is that the PVC shell in the cold is destroyed. It should be noted that this option has another important significant plus - in case of breakdown of the cable sheath, the insulation layer localizes the distribution current leakage beyond, which will protect maintenance personnel from electric shock upon contact with it.

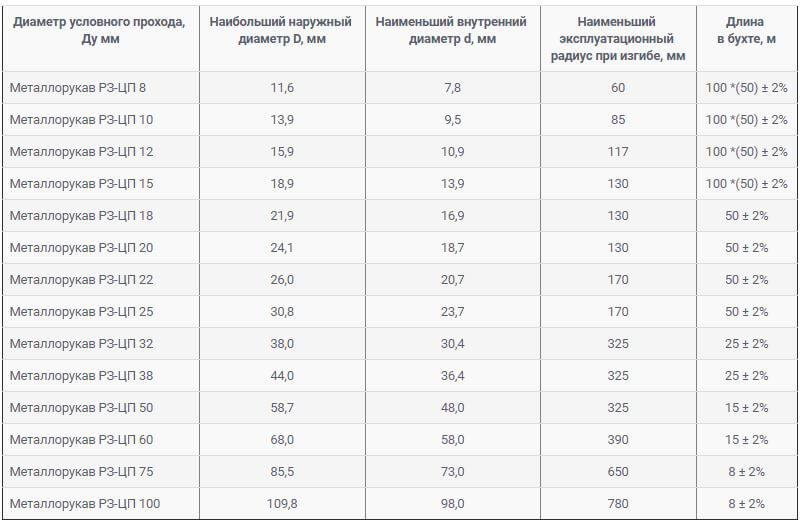

Technical characteristics of metal hoses РЗ-ЦП and МРПИ:

What to choose

The criterion for choosing the type of metal hose should be the state of the environment in which it will work.

An unpressurized metal sleeve with a cotton seal can be used in interior rooms, the humidity level of which does not exceed the norm. With polypropylene gasket - indoor areas with a high moisture content, in baths, laundries, showers, and also outdoors.

The sealed version with PVC coating is recommended to be laid in trenches, tunnels, ventilation shafts, explosive rooms, underground workings.

The use of metal hoses for electrical wiring made of stainless steel is advisable in rooms with a high concentration of aggressive chemicals, in storages of acids, alkalis and salts.

Important! To carry out installation work on laying the cable in the metal hose, you will need a whole list of related devices, such as mounting brackets and couplings, which provide connection and entry into the hose distribution devices. The couplings can be straight and angular, they relate to the category of threaded connections with a thread pitch identical to the pitch of the turn of the plate.

Finally, we recommend watching a video review of the metal hose for electrical wiring:

So we examined the types, sizes and specifications of the metal hose for the cable. We hope that the information provided has helped you determine the choice of a suitable execution option for your own conditions!

It will be useful to read: