Comparison of the collector and brushless motors

Our life is unthinkable without all kinds of mechanisms. These are children's toys, household appliances, complex electronics, industrial equipment, etc. All of these instruments and devices are used electric motorsworking from various power sources. In this article, we decided to consider the difference between collector and brushless motors, as well as which type of motor is better and why.

Collector motors

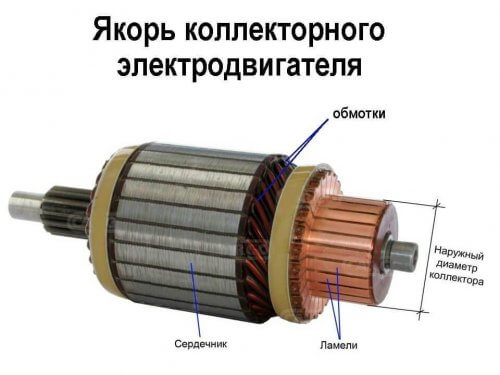

The electric motors used in children's toys have small dimensions and low power. Constructively commutator motor represents two permanent magnets mounted on a stator, and a rotor (anchor) with windings. Note that on the stator there may be field windings, instead of permanent magnets.

A constant voltage is applied to the windings through the collector lamellas. Graphite brushes are used to supply voltage. In low power engines, copper plates are used as brushes.

Collector motors are powered by both direct current and alternating current. To connect the power, they have two wires.

Brushless motors

The name of the electric motor indicates the absence of a current collector. What is the main design difference. This allows you to reduce friction losses and increase power. In this case, permanent magnets are mounted on the rotor, and the windings are placed on the stator.

Are issued brushless motorsin which magnets are mounted on the housing. In this case, the housing acts as a rotor.

To start the engine requires a special device (controller or switch), which increases the cost of brushless motors.

Pros and Cons of Compared Engines

Electric motors with a collector are used in children's toys, car models, ship modeling, etc. More powerful devices with field windings are used in the automotive industry, household appliances, in a lathe or drilling, etc.

Widespread use due to:

- Low price.

- Simplicity of management. To adjust the speed, it is enough to have a rheostat, and to reverse, change the polarity in the excitation circuit or armature.

- Can be connected directly to the mains.

- The rotor speeds can be changed over a wide range.

- Small inrush currents.

But with the simplicity of the device, collector motors have disadvantages:

- Low efficiency.

- Limited service life.

- The need for ongoing maintenance.

- Low reliability of the device.

However, such engines are not used in all industries. They must not be used in hazardous areas. When operating at high speeds, the collector and brushes quickly fail.

As a result, a decrease in power occurs, and the current-carrying brushes begin to sparkle.Such a structural difference leads to a quick failure of the collector lamellas; interference in the radio equipment.

You have to change the brushes and grind the collector, which reduces the life of the engine. This is the main disadvantage of such devices.

In brushless motors there is no collector. This is the difference between brushless motors from collector motors, and therefore the above disadvantages are absent.

The advantages of such electrical machines are:

- The absence of rubbing parts reduces the friction power loss. It is not necessary to constantly monitor the condition of the brushes, as they are absent. This difference allows to increase the overhaul period.

- The possibility of using the housing as a working body. This design difference allows the use of mechanisms directly as wheels.

- Brushless motors, unlike collector motors, are more durable. Moreover, they are less susceptible to overheating, as there is no collector and brushes that become very hot during operation.

- Instantly gaining momentum.

- They can be used in all industries, in fire and explosive rooms. Due to the lack of a collector, sparking does not occur, which is why they are better.

But this type of motor has a significant drawback: brushless models can only be used with a switch driver. Using this device, the operating modes, speed and direction of rotation are set. The cost of brushless motors is much higher. The difference in cost can be significant. This is how they differ from collector devices.

Light weight and high power - this is what is better combined in devices with remote control, for example, for a quadrocopter, where the range and flight time depend on weight and efficiency.

Conclusion

So, to summarize and denote the difference between the collector and brushless motors, listing their features.

Commutator motor:

- There are brushes and a collector that spark and wear out.

- It is necessary to service more often, respectively, and the service life is not too long.

- It is easy to adjust the speed only by changing the voltage.

- To reverse, you just need to change the polarity.

- The two previous facts allow them to be used in budget devices without complex electrical circuits.

Brushless motor:

- To start, you need a controller, which, although not too expensive, but increases the final cost, circuitry and weight of the product.

- They weigh less than collector, with the same power (but this is partially offset by the previous fact).

- There are no brushes and a collector, therefore they do not require maintenance, they do not spark.

- Longer service life, it is limited only by the resource of the rotor bearings.

- They usually cost more than collector ones.

- Often give more torque to the shaft and speed.

- In the presence of shaft position sensors provide greater stability of revolutions when the load changes (rigid mechanical characteristic). This is especially important when used on machine tools and hand tools.

From the author:

I will add that it is impossible to say unequivocally which is better or which is more powerful, you can find a collector motor the size of a refrigerator, or you can find a brushless motor the size of a nail. At the same time, both will perfectly perform those functions that are designed and used in specific devices, taking into account the requirements for their reliability and operation characteristics. Each type of electric drive is good in its own way and ideal in design as such.

Now you know what the difference is between a commutator and brushless motor, as well as what are the pros and cons of each version. We hope the information provided was useful and interesting for you!

Related materials: