Why is the neutral wire heated and is it dangerous

Where is the neutral wire heated

Most often, zero is heated in a shield at the entrance to the house or another distribution board. It can be heating in the terminal block on the input circuit breaker. This phenomenon is also observed if you have installed automatic plugs or plugs with fuses, but in this case there are more places that can get warm. Here, the screw terminals for connecting the wire and the thread (cap) of the plug, as well as other connections, can be heated.

In simple words, there are three factors why the neutral wire or terminal heats up:

- Too high load.

- Poor contact due to loose cable tightening.

- Poor contact due to oxides or soot.

If the terminals are covered with soot, then an avalanche-like process of aggravation of the situation occurs. For example, carbon deposits appeared due to poor crimping or short-term wiring overloads, as a result of which increased contact resistance. Any resistance is heated when a current flows through it, and because of this heating, carbon deposits become even greater. Consider each of the reasons for the example of situations and their solutions.

Important! Before performing all work in the wiring, you must disconnect the power supply. If there is no way to do this, then using an indicator screwdriver, make sure that it is zero, not phase. Also, if you disconnect the neutral wire and do not disconnect the phase, and at least one of the light switches or electrical appliances is connected to the network, then you will have "two phases", that is, the potential of the phase dangerous to life will appear on the neutral conductor.

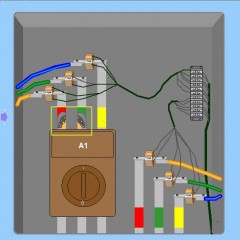

Identification of bad contact in the machine

To connect the wires to the circuit breaker, most models use screw clamps. In the photo below you see the consequences of a poor connection in the machine:

To eliminate it, you just need to remove the wire and clean it from oxides and carbon deposits, and then clean the terminal strip in any way:

- It is most convenient to use a small file, it fits perfectly into the terminal block.

- If there is no needle file, you can scrape away the soot with the tip of a slotted screwdriver of a suitable size or with an awl.

After this, you need to tighten the screw well and tighten the wire, make sure that it does not hang. If the zero on the machine was warming for a long time, then its contacts could be damaged. If the heating does not disappear after cleaning the contacts, then replace the machine completely. In a difiltomate, the causes of zero heating and its elimination are similar.

Zero plug heating

Usually a safety plug is installed at zero, but often you can meet an automatic plug, in principle, it is a functional analog of the machine. In the picture below you see the cork and its cartridge (holder), into which it is screwed. In this case, there are two possible places of heating - the thread of the cork holder and terminal blocks, to which conductive conductors are connected.

Pay attention to the surface of the holder: if it is cloudy and oxidized - this may be the reason that it is warming, it can knock out plugs, then you need to clean it with a file or sandpaper. They just need to be cleaned, as are the screw terminals.

In the outlet, the zero heats up for the same reasons for poor contact.

Other causes of heating

Wires and contacts, as already mentioned, can get warm due to increased load. There are three options for the problem:

- Conductors are very thin, you can notice heating when the load on the wiring has increased, for example, in winter, when you started using an electric heater. Then the wires in the shield must be replaced with thicker ones.

- Zero heating in the tire. In this case, the most likely problem is poor contact of the screw terminals of the bus. To ensure contact, do the same as with the machine - clean and tighten the screw.

- The "excess current" flows through the neutral wire. This is possible if your neighbor uses a zero to steal electricity or due to unintentional wiring errors. You need to check all the connections, you may need to open the gates in the walls or use the device to search for hidden connections.

In the counter, zero is extremely rarely heated; it is used there only for measurements.

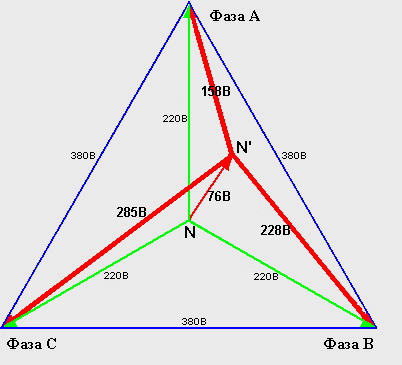

What is the danger of zero heating

If the zero heats up, it can burn out. In a single-phase network, this is practically not dangerous, in the worst case it just happens zero break and two phases appear in the outlet, as described above, respectively, your wiring will not function. If a neutral wire burns out in a three-phase network, for example, on an access switchboard, then phase imbalance. As a result, the voltage in each of the phases can significantly exceed the nominal 220 volts, because of which your household appliances and other electrical appliances can fail.

Also, heating occurs on a twist, especially if aluminum is twisted directly with copper, in which case you need to use terminal blocks or a bolted connection. In this case, direct contact of copper and aluminum is excluded by laying a washer between them.

Now you know why zero is heated in the wiring and how to eliminate this so dangerous phenomenon. If you find excessive heat, immediately start searching for the cause that caused the emergency, or call an electrician, as further developments can be disastrous!

Related materials: