Description of the characteristics of the cable brand KGN

Labeling Explanation

The first step is to tell how the abbreviation is deciphered. According to existing standards, the decryption is as follows:

- K - cable;

- G - flexible;

- H - insulation layer made of Nairit rubber (non-combustible).

As you can see, the marking is quite simple and straightforward. There are several more varieties, namely KG-HL (cold climate) and KG-T (tropical), but we will definitely discuss these brands separately in the following publications.

WITH KG cable specifications You can find in the corresponding article!

Design

So, the design of KGN is presented as follows:

- The conductive core is made of copper, its structure is multiwire, the shape is round, flexibility class 5 in accordance with regulatory document GOST 22483.

- A dividing layer may be applied on top of the core to prevent insulation from sticking to it. The material of this layer is synthetic film.

- The insulation itself is rubber, wire color marking complies with existing standards.

- If the cable KGN is multicore, the wires are twisted together in increments not exceeding 16 diameters along the entire length.

- On top of the rubber insulation, a release layer can be laid in the form of talc or a synthetic film, which prevents adhesion between the shell and the inner insulation.

- The shell is made of non-combustible rubber, which is also oil resistant, which gives the conductor enhanced performance.

In the photo below, you can take a closer look at the design of the KGN:

main parameters

So we went to one of the most interesting questions for you - a description of the parameters of the conductor. Technical characteristics of the KGN cable are as follows:

- The rated voltage is 0.66 kV (alternating) and 1 kV (constant).

- AC frequency 400 Hz.

- Operating temperature from -30 ° C to + 50 ° C for the KGN brand and from -10 ° C to + 55 ° C for the tropical version of KGN-T.

- The minimum gasket temperature is -15 ° C (without preheating before installation).

- The maximum heating of the conductors in the operating mode is allowed no more than + 75 ° C.

- The minimum bending radius during cable laying is from 8 outer diameters.

- Construction length of the conductor with a cross section up to 35 mm.kv. not less than 150 meters, with a cross section from 50 to 120 mm.sq., usually 125 meters and with a cross section of 150 mm.sq.and above the construction length of the cable KGN should be at least 100 meters.

- The service life is only 2.5 years from the date of production.

- Guarantee the service life is half a year from the moment the cable line was launched, but at the same time a year from the date of production.

- It is made according to TU 16.K73.O5-93.

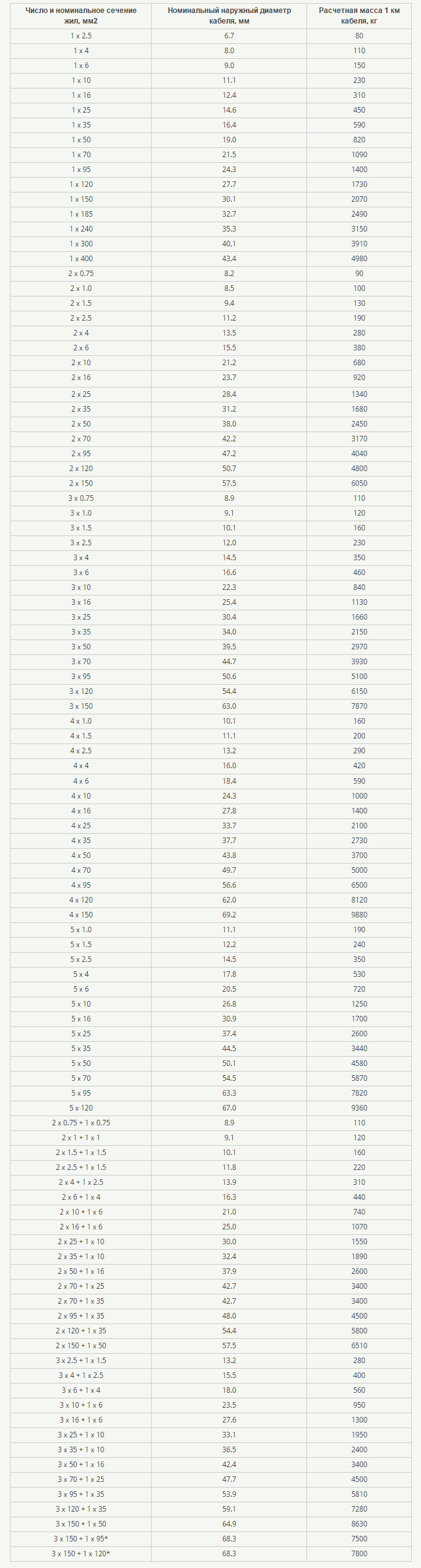

As for the other technical characteristics of the KGN power cable, we provided them in the tables. If you are interested in all the cross-sections of the conductor, the weight and the outer diameter of each size, check out the data provided below:

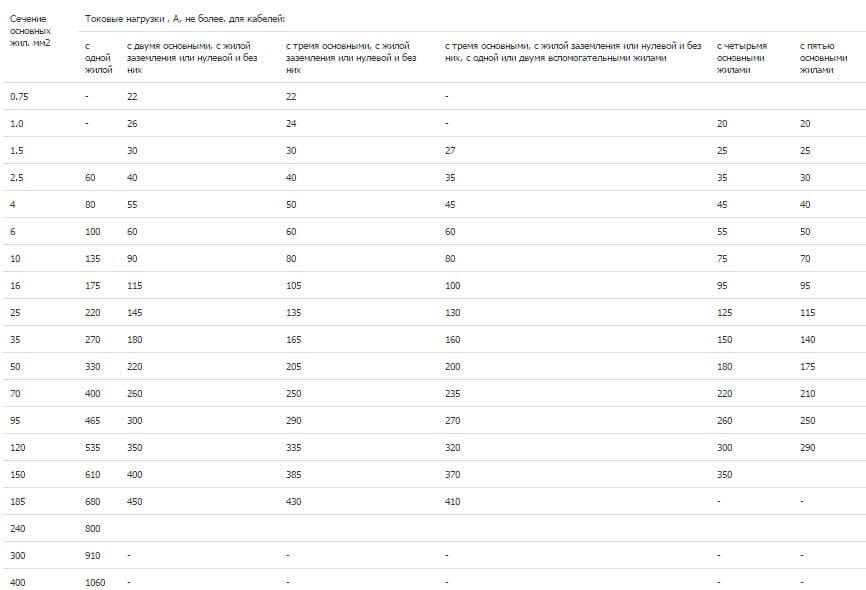

The long-term permissible current to the conductor is:

So we examined the main characteristics of the KGN copper cable. It remains only to tell you where it is used and which manufacturers produce this brand of cable products.

Scope and purpose

Due to its parameters, this conductor can be used in conditions with high humidity, even under water. It, in fact, was made for use in shipbuilding. In addition, KGN is used in aggressive environments, for example, in mines, for connecting mobile electrical equipment and mechanisms. For laying in the ground it is better to use armored cable products, for example, VBBSHV copper cable.

As for residential buildings, it is advisable to use a conductor only if the premises have natural ventilation, and the wiring itself is not stationary (temporary). Often KGN finds its application for power supply of basements.

An important nuance should be noted - installation of the conductor in question by air is allowed only if it is additionally protected from sunlight. This is due to the characteristics of the insulation, which is not resistant to ultraviolet radiation.

Factories manufacturers

Well, the last thing I would like to talk about is which KGN cable manufacturers are the most reliable today. So, there is no doubt about the production quality of this brand of cable products if it is produced by the following factories:

- "Electrocable" Kolchuginsky Plant ";

- Camcable;

- "Rybinskkabel";

- "GC" Sevcable ".

Nevertheless, if you doubt the quality of the purchased goods, we recommend it yourself determine cable cross-sectionto make sure that the specifications declared by the factory are actual!

By the way, an import brand NSSHOU can be considered an analogue of the conductor. Therefore, if you do not know how to replace the cable in question, check out the NSSHOU parameters.

So we examined the main technical characteristics of the cable KGN. We hope the information provided was useful to you!

Surely you do not know: