What are the DIN rails?

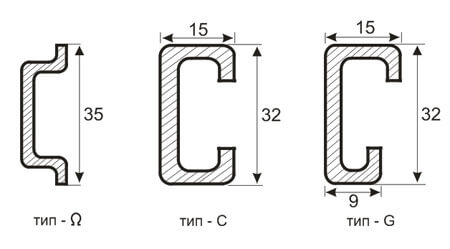

Today, din rails are distinguished by such technical characteristics as size, shape, manufacturing material and design features. The first thing to start with is the types of profiles that can be:

- Ω-shaped. The most popular form used in switchboards for automatic machines, an electricity meter, etc. It looks like in the picture:

- C-shaped. The ends are bent inward, so hardware clips can be installed on such a DIN rail or terminal blocks.

- G-shaped. It is used extremely rarely, according to the purpose it corresponds to a rail in the form of C.

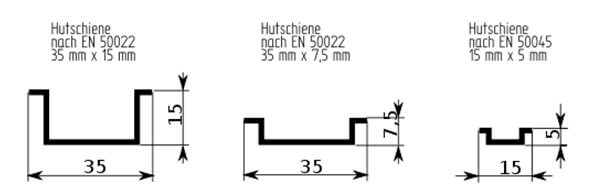

As for the dimensions, according to the standard GOST R IEC 60715-2003, the width and height of the product can be as follows:

We draw your attention to the fact that a din rail in the form of an omega, which is also called TN-35 (generally accepted designation), can have three sizes, namely:

The length is different, depending on the manufacturer. Most often they produce slats with a length of 7.5 cm to 2 meters, which is quite enough for shields from 4 to 96 modules.

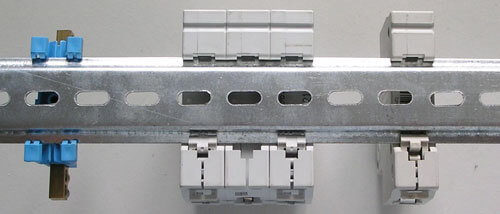

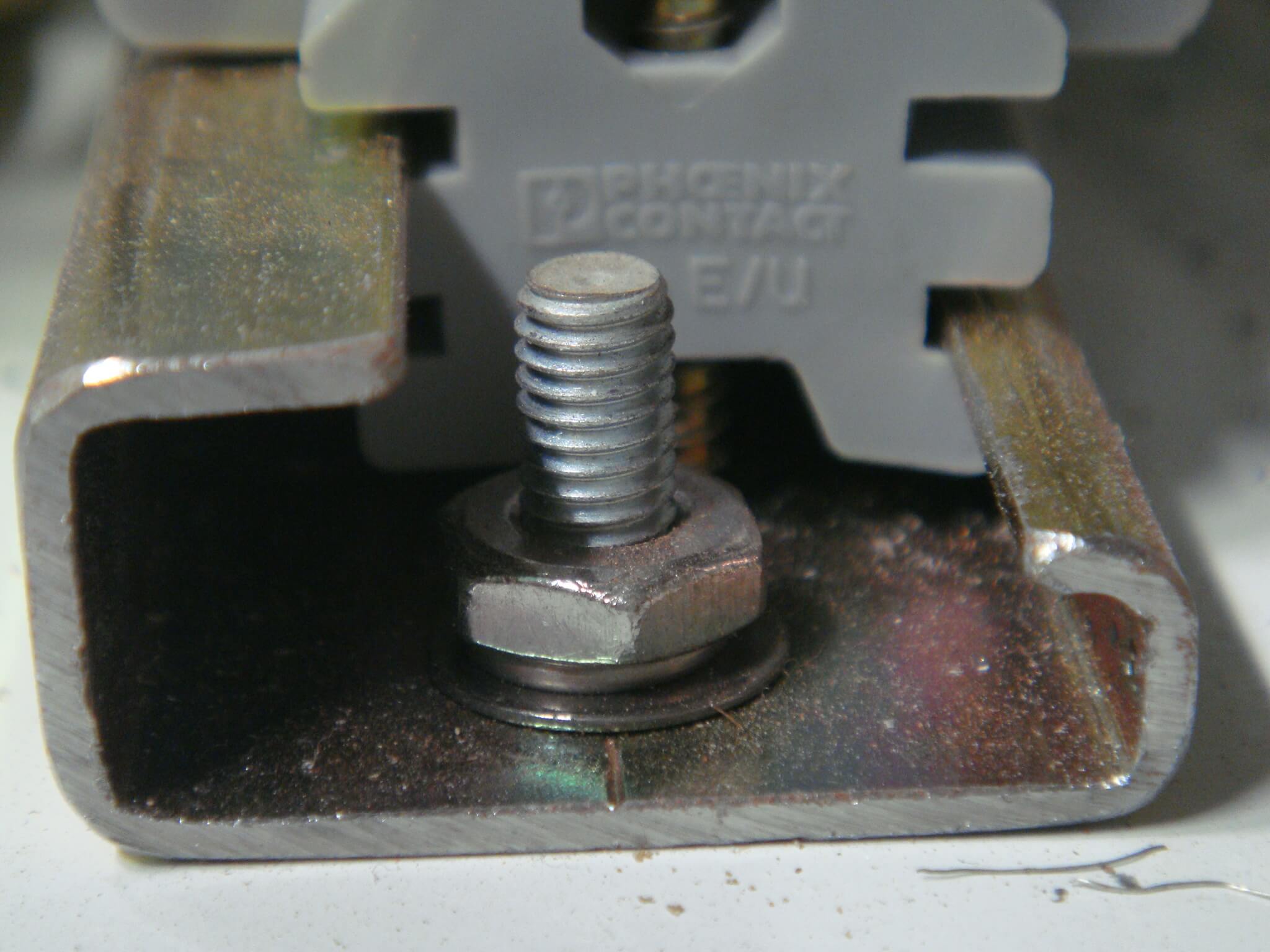

It should also be noted that the strips are perforated (with holes) and cast. The advantage of the former is easier installation, as just screw the steel rail through the finished holes. The perforation pitch is usually 10-15 mm, which is quite enough for easy installation. Cast (non-perforated) DIN rails are more reliable, as Do not bend if you attach a lot of machines to them in the cabinet. By the way, modular machines are mounted on a DIN rail as follows:

According to the material of manufacture, the strips are divided into aluminum and galvanized (from stainless steel). In electrical work, the second option is more often used.

In addition, there are certain types of DIN-rails, namely: deep and reinforced. Each of them is applied in its own special case.

Well, the last thing I would like to tell you about is which bar manufacturers are considered the most optimal in terms of price and quality. Among electricians, DIN-rails manufactured by ABB, IEK and DKS are popular. These companies have pretty good products and at the same time moderate cost.

It remains only to watch the video, which clearly shows how to mount the machine on a din rail, and also what is the difference between the manufacturers of products:

That's all I wanted to tell you about the types and sizes of DIN rails. Now you know what strips are, how they differ from each other, and for what they are actually used!

It will be interesting to read: