How to choose a cable for the welding machine and what should be the cross-section

Cable Requirements for the Welder

Firstly, if you choose a cable for connecting the mass clamp and electrode holder to the welding machine, you need to consider the following features:

- Welding machines of any type give significant currents - from 10-20 to 400-500A. In this case, inverter-type household welding machines are usually rated at 200A with a deviation of 50A in each direction, and industrial welding transformers give out currents of 400A as well.

- In the welder's work, a wide variety of tasks are encountered, both simple seams in convenient positions, and welding of products of complex shapes or in hard to reach places.

- In addition to various tasks, it is necessary to cook both in very hot rooms and in winter in the cold.

- For transportation of equipment, the cable is rolled up.

It follows that the cable must satisfy the following requirements:

- The power welding cable must be flexible in order to provide ease of manipulation with the electrode or torch for the welding semiautomatic device.

- The conductor must have a thick insulation and be resistant to aggressive environments, impacts and tears.

- To work in the cold, the conductor must be frost-resistant.

- Welding of metals occurs under reduced voltage, but high current, so there is a separate requirement for the cross-section of the wires for connecting the electrode holders and ground. This means that the wire must be thick to minimize voltage drops and losses.

- Must withstand repeated bending and unwinding / unwinding during transport.

Suitable brands and types of cable

The most popular option for a welding machine is KG cableIt is a flexible single-core cable with a multi-wire core in rubber insulation. KOG is also popular with increased flexibility. There is also a specialized KS, these are the main brands of conductors that are used for welding.

The name may also include a performance note:

- T - tropical version, can work at ambient temperature up to +50 (according to some sources 85) degrees Celsius.

- KH or HL - frost-resistant, it works at -60 degrees Celsius.

And also the prefix P - an additional sheath of a core from polymeric materials.

The numbers in the marking indicate the number of cores and their cross-section, for example: KG 1x16 says that it consists of 1 core with a cross-sectional area of 16 square meters. mm

Section and length selection

The cable cross section for the welding machine is selected based on the current. For an approximate assessment of the required section, we have prepared a table:

| Section, sq. mm | Current, A |

| 1x6 | 80-100 |

| 1x10 | 120 |

| 1x16 | 189 |

| 1x25 | 240 |

| 1x35 | 289 |

| 1x50 | 362 |

| 1x70 | 437 |

| 1x95 | 522 |

Cable length is a subject of controversy for many craftsmen. With increasing length, with a constant cross section, its resistance increases, as well as inductance. If you select a cable that is too long, you will not have to wind it into a coil when welding near the welding machine, but if you select a short one, you will have to constantly move the welder.

On the other hand, if you do not cook large volumes in production, then the length of the welding cable of 5-10 meters will be optimal, and the device should be connected to the network through an extension cord. Moreover, inverter-type amateur devices, which have been used more often recently than others, are quite compact and light, so carrying them around will not cause any special difficulties.

If nevertheless you need to lengthen the existing wire, sleeves are best suited.

Cable for connecting the welder to the network

In addition to connecting the electrode and ground to the welding machine, you also need a cable to connect the welder to the mains. No matter what type of apparatus, inverter or transformer, the welding current reaches hundreds of amperes, but the supply current is much lower. It can reach about 30-50 amperes, depending on the power of the welder.

Therefore, it does not need a cable as thick as it is for an electrode holder. It is calculated depending on the distance from the connection point to the mains. If you have a single-phase inverter type household appliance for 220, or a two-phase for 380V transformer, then a copper conductor with a cross-section of conductors of 2.5-4 sq. Mm is suitable. By the number of cores, a two-wire cable is used if the object does not have grounding and a three-wire cable if you connect to a grounded outlet.

For convenience, a network cable of 3-5 meters long is sufficient, and for carrying around the territory of the object use a carrier with a cross section of 2.5 square meters or more. mm, if the carrying length is 10-20m. For reliable operation of the device from a longer carrying, for example 40-60 meters, it is better to take a cable with a cross section of 4 square meters. mm

If you intend to use a long carry, it is better to buy an extension cord with a reel, then the cable will not get tangled under your feet and will last longer. However, in the coil it will be poorly cooled so that it does not overheat, it is better to take a section with a margin.

For industrial three-phase devices on 380V, four-core copper cables with a cross section of 4-6 square meters are used. mm, or aluminum - with a cross section of 16 square meters. mm Do not forget to check the correct connection and direction of rotation of the cooling fan, if present.

Terms of Use

Instead of a conclusion, we will talk about how to choose and operate a welding cable correctly:

- Connect the wires to the welding machine with cable lugs, they are crimped or soldered.

- For lengthening and joining several segments using sleeves or another method of connection, except twisting.

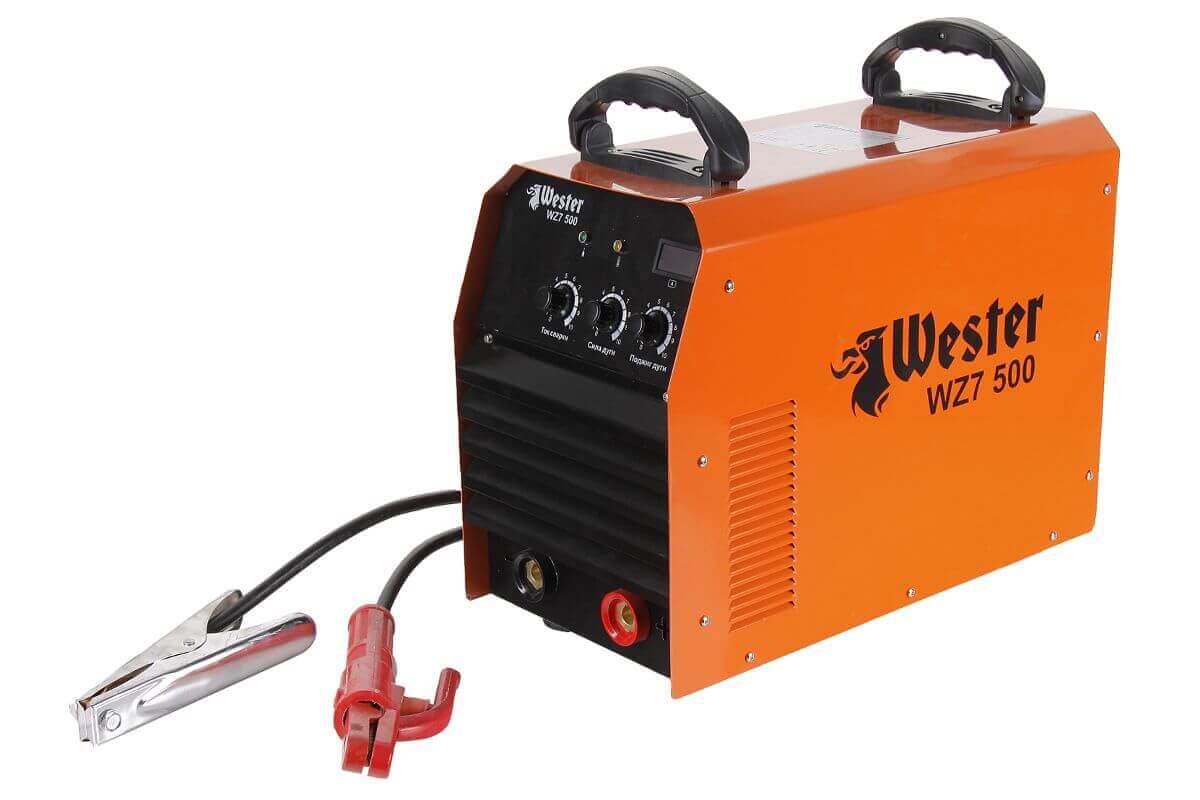

- In welding inverters, wires are usually connected using bayonet connectors. This must be taken into account and bought in advance, otherwise you will not be able to use a cable with such a welding machine. With their help, you can quickly change the polarity of the current.

- Do not buy wires of too long lengths and cross sections if you are not going to use its full potential. This will lead to an excessive mass of conductors and difficulties in operation.

- Do not pull the welder closer to you by the cable, so as not to damage them.

- Do not exceed the permissible current through the wires.

- An extension cord with a coil will become indispensable when the welder moves frequently around the object.

Now you know how to choose a cable for the welding machine by section, make and length. Finally, we recommend watching a useful video on the topic of the article:

Useful on the topic:

In the network and literature, a lot of descriptions of how to choose a cable for a certain load. And everything seemed to be right, but the question does not bother me: why do the MOFSET transistors' conclusions in the output stages of the welding inverters not burn out? After all, their cross section should not withstand such a current. As they say: where it is thin, there it breaks.

Because the transistor leads correspond to their parameters, because in the SOT-23 package there will be no device with a rated current of a couple of amperes, and in TO-220 it is easy. Yes, and what kind of current is it? According to the scheme, they are located in the primary of the pulse transformer, the voltage there is higher than the output, and the current is less ... the length of the terminals is rather short, although the terminals are thin, they are flat, so if you count the cross-sectional area it will not be as small as it might seem .

Can I use a KGE cable for welding?

Quite! Only by cross-section, see which one is needed!

What cable is needed for Inverter Welding Kemppi 202 Its cable is overheating and very short wanted to change the cable in my opinion it is not a copper cable aluminum subspecies it seems honey turned aluminum

Recently I bought a semiautomatic device 305 steel ... the declared weight is 9.5 kg .. I don’t get too tight. And noodles mmm .. mass 1.3 m ... .cooker 1.7m .. wire up to 1mm ... electric ... 1.6-5mm. At 305A declared .. ,, Noodles ,, 16mm2..From the tables grove. 189A holds .. I have a QUESTION whoever knows .. CAN I ADD A CABLE UP TO 25MM2 ... MASS 2 ... 3 .. METER .... HOLDER ..3..4 METER .. Who knows, advise .. I can’t write down the welding passport, you can whether to add cable ... Someone says .. that no way .. Thank you in advance, advise ..