How to check the power tool and what is it for?

Electrical safety tool classification

When operating an electric tool, it is worth knowing that according to the current GOST it is divided into several protection classes. The check of a portable power tool, its frequency and methodology directly depends on this.

- 0 - has only operational insulation without grounding devices and connections;

- 01 - there is a working insulation and a grounding element, however, the cord itself, which is equipped with the tool, does not have a ground wire;

- 1 - has a working insulation and a grounding element that is connected through a cable having a corresponding output;

- 2 - equipped with double insulation, that is, electrical wiring and live parts are isolated, as well as the housing is made of dielectric material;

- 3 - this class of power tool is connected to a reduced safe voltage - not more than 42 Volts, while the devices are not subject to grounding.

Most often, in everyday life and at the enterprise, workers use a class 2 power tool, since it has sufficient insulation so that a person is not injured.

Tool Testing Methodology

It is allowed to use a household and industrial power tool that has passed the test. For this, a clear algorithm has been developed that must be followed by anyone who wants to work with it. In this case, you need to clearly understand the difference between verification and verification.

Verification - These are tests that are carried out in special laboratories located at each large enterprise. The tests include:

- Determination of the availability and serviceability of the ground circuit by using a special ohmmeter - one end of the device is connected to the terminal on the plug, and the other to the ground located on the instrument itself. Measurements should show no more than 0.5 Ohms, which meets the safety conditions for using the tool.

- The measurement for integrity and quality of insulation is checked by a megohmmeter at a voltage of not more than 500 V for a power tool designed for an operating voltage of 220 V.You can not twist it quickly, this will be enough to see the insulation resistance of the tool. At the same time, you must definitely remember to press the button that turns on the electric tool. The device must show an insulation resistance of more than 500 kOhm, if this value is less - work with it is prohibited.

- Further, a trial test of it is carried out when idling for 5-7 minutes.

A power tool can also be checked with increased voltage. In this case, a tool with a voltage of up to 50 Volts is checked with a test voltage of 550 V. If the tool is designed for voltages above 50 V, but with power up to 1 kW, the test voltage must be 900 V, above 1 kW - 1350 V. Tests are carried out for 1 minutes.

Check - carried out by visual inspection and inspection. It is necessary to check not only the case, but also the cord connecting it to the source of electricity. Pay attention to:

- The integrity of the body, it can be cracks and breaks.

- The power cable, there should be no visible drying out, damage, grinding, as well as signs of burning and heating. Particular attention should be paid and check the entry points of the electric cord into the housing and the plug.

- The plug and its contact part, which will be included in the network, are inspected and checked for integrity.

The check should be performed before starting work, and before switching on after switching to another workstation. Naturally, professional laboratory calibration is carried out only at large enterprises and firms, in the home, an employee, at least before work, should carefully inspect a power tool taken in his hands.

If we talk about the timing of checking a power tool, then according to existing regulatory rules, periodic testing of a tool should be at least every year, and it is necessary to check a power tool, as indicated earlier, before each use. If manual electrical equipment is used in extreme climatic and industrial conditions, it is recommended to check it with a megohmmeter at least once every 10 days.

An important point! When checking a tool in an enterprise, you first need to look at the date of the test. If the date is overdue or there is no tag for testing the power tool at all, then it is forbidden to operate it - it must be removed and taken for testing.

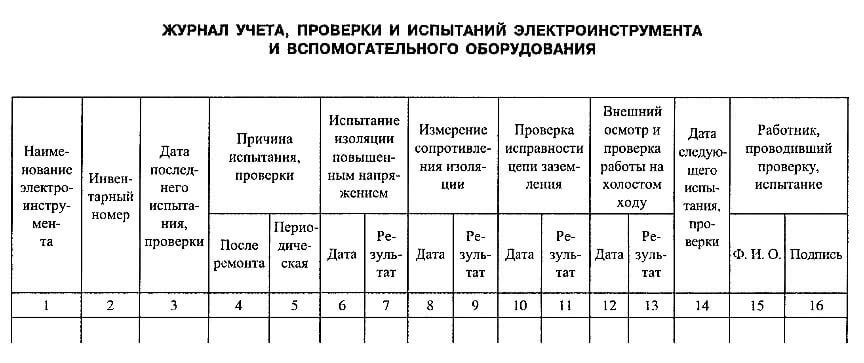

Registration and accounting checks

Power tools used in enterprises for professional purposes must be numbered and entered in the register. The management of the enterprise and the structural unit need to organize clear accounting for the storage, operation and inspection of manual electrical equipment. All necessary information is recorded in a special prepared journal, and according to the results of verification and verification, an appropriate protocol is issued. And also a mandatory measure to ensure the safety of this equipment is a qualified instruction of personnel with a knowledge test, in which the verification methods, as well as the rules for using it, are announced under the signature. One of the important criteria for checking and safe operation is the use of auxiliary equipment, such as carrying and extension cords. They also need to be checked once a year and this is the direct responsibility of the person responsible for the electrical industry.

As practice and statistics show, whoever conducts at least a regular quality inspection is less likely to come under deadly stress. It is especially necessary to be careful when working in wet rooms (basements, bathrooms, etc.) and in the absence of a modern RCD in the power system (residual current device), quickly responding to breakdowns in the circuit.

In the end, we recommend watching a useful video that shows how to check the quality of an electric tool before buying it:

This technology is used to check and test power tools. Now you know who conducts the verification work and with what frequency!

It will be useful to read: